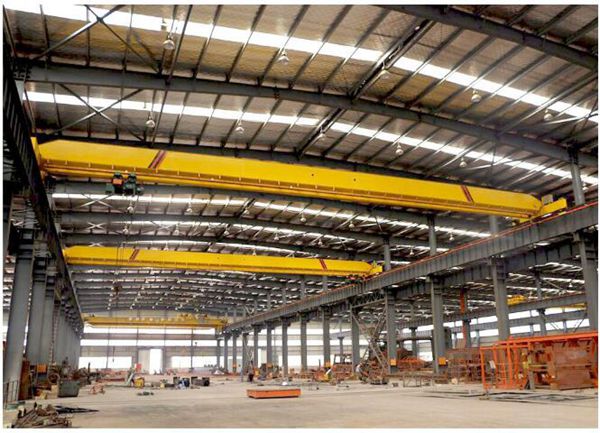

Single girder overhead crane has one girder across the middle for support of the trolley, and the suspension monorail can move more smoothly and quickly. This aids in a more cost effective and efficient crane operation.

An under running single girder crane setup is an operation where the trolley is suspended directly under the girder. This allows a much more efficient running arrangement with the need for support columns that are interfering. The under hung system depends on the lower flange of the runway beam, which make a natural runway for the crane attachment.

The single girder under hung crane can operate on multiple runways that can maximize the depth of the bridge girder which can decrease the weight of the operating equipment. The result is lower costs for the equipment and lighter design requirements when it comes to making and building the structure of support.

A second advantage of a single girder, under hung arrangement is the fact that that crane setups can be operated side-by-side without have to make adjustments in the entire scheme of things. Where the bays in a building are wide and multiple under hung runways can be installed where they are adjacent to one another. This gives them the ability to pass each other and all operate together. Ellsen Company, a famous crane supplier in China, supplies customized single girder cranes with high quality, cost-effective products for you http://ellsenoverheadcrane.com/single-girder-overhead-crane/ .

Single girder top-running cranes cannot accomplish this feat because they will have to be supported with extra auxiliary columns or other types of support.

Still another advantage of the single girder, under hung cranes is that they can be operated with mechanisms that interlock with one another, causing the ends of adjacent cranes to lock together ends which allows the transfer of carriers from one crane to another. Each end of the cranes can interlock in this manner, to give total flexibility as to length of a track for the carriers to run on.

When a setup that uses multiple stations of interlocking and connecting one crane to another is used, it eliminates the need for load re-handling, which will decrease the costs for material handling. This is much more cost-effective than buying and installing a completely new crane. By using this interlocking type of strategy, you create an entirely fluid system which decreases downtime, and can even reduce or eliminate the need for additional lifting equipment.

Single girder with under-running cranes are particularly ideal for setting up monorail systems that transfer the trolley and the hoist from one interlocked crane to another in processes that transfer materials along a fixed path for some distance.

Systems using this method can even be set up to transfer materials to different spurs, multiple spurs, or any configuration that meets the needs of the process. Great flexibility is provided as the single girder system is more flexible itself as it requires no additional support from building girders, as the loads are of a lighter nature.

Since the single girder bottom-hung are lighter in weight, they are easier to make to conform to more diverse and lighter weight processes. More details about single girder crane and other types of cranes, you can visit http://ellsenoverheadcrane.com/.

https://youtu.be/cj7WqyTQaIE