Nearly every city or municipality in the world has a garbage problem, it’s piled high in landfills, being thrown in rivers, and it’s overflowing in the streets. Two huge components of garbage that take many thousands of years to degrade are waste plastics and tires. Tires are especially hard to dispose of because they rise to the top of landfills continuously, filling up with water and breeding mosquitoes, and can catch fire releasing toxic fumes. However, there is now an economical way to recycle tires and plastics by using a process called pyrolysis. Our latest continuous waste tyre pyrolysis plant can effectively finish this tire pyrolysis process by using high temperature heating.

Simply Burning Your Garbage Isn’t The Answer

Some will say that most of the garbage should be shredded and then burned to reduce it to ashes, reducing the volume, and making the tire problem disappear. However, the pollutants released when many waste products burn are highly toxic. When things burn, they mix with oxygen and the combination chemicals can be lethal. This poisons the air, the land, and if leached into the water, kills all the fish.

In nearly every country waste incineration has been tried, but the result is toxic for those around the incineration plants and anyone down wind or down stream as well. Regulations have been imposed that make burning garbage illegal or too expensive for most of the burning plants to survive. If you need the help of the tyre recycling machine, Beston is really a kind of useful source for you. Get a quick quote from them https://bestonmachinery.com/pyrolysis-plant/cost/.

Now With Pyrolysis, There Is A Safer Way To Recycle Wastes

OK, so you’re thinking that pyrolysis is going to be polluting the same as a waste incinerator, but that’s not the case. The simple way to explain pyrolysis is that it bakes the waste at an extremely high temperature while withholding the oxygen needed to catch fire. Without the oxygen, the waste separates into some of its basic components like oil, gas and carbon that can be used in many industries as ingredients to make other products.

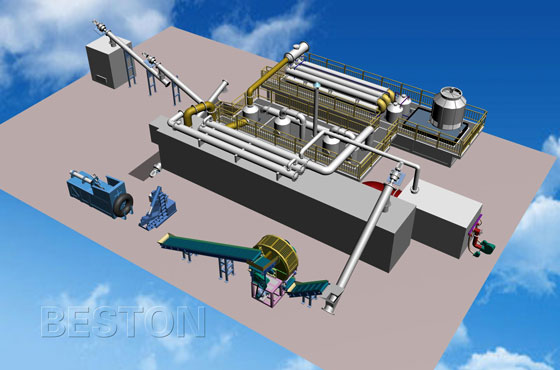

In fact, a continuous waste tyre pyrolysis plant can actually consume many tons of waste tires per day while producing usable oil, carbon black, and methane gas. When captured, these waste products can be sold to industrial clients and the pyrolysis plant can actually be profitable as well.

Recycling Plastics Is Difficult Because Of The Different Types

One huge problem with recycling all of the plastic items that get thrown into the landfills is that each type needs to be separated and recycled differently using a special process. All of this separating and sorting has to be done by hand using the codes stamped into the bottles. This is a very labor intensive, high cost, dirty job for humans to do. Plus, many of the plastics aren’t recyclable at all.

However, with no sorting, mixed plastics, tires, rubber, waste oil, plastic car parts and even wood waste can all be fed into a continuous waste tire recycling plant and then turned into basic ingredients that can be sold for a profit. The machine can work 24 hours per day, shredding, baking, and separating the gas, oil and carbon for later sale.